Forklift Attachments

Forklift attachments are a critical component in material handling, making it possible to move certain loads safely and efficiently.

The importance of having “the right tool for the job” cannot be understated – the appropriate forklift attachment will safeguard the productivity and integrity of your operation, eliminating potential damage to goods, and mitigating injury risk to personnel.

In simple terms, attachments improve the versatility of your forklift to ensure you have a fit-for-purpose efficient material handling tool.

Given there are so many different types of forklift attachments available, it is crucial to choose the correct attachment type for your application.

What are examples of forklift attachments?

From side shifters to man cage risers, drum rotators to slip-on tilt jibs, telescopic long jibs, and short jibs, there are numerous options when it comes to modifying your forklift to meet your material handling needs.

The right forklift attachment will help you to:

- Safely carry personnel for maintenance purposes

- Manoeuvre loads into difficult positions

- Rotate loads whether they be cylindrical or square

- Handle and dispense drums of liquid or product

- Hold bags of product for loading or unloading purposes

- Sweep indoor or outdoor areas for cleanliness

- Transport long rolls of product

- Load and upload vehicles more efficiently

- Clamp loads including paper, plastic, waste etc.

Do forklift attachments reduce capacity?

In short, yes.

Nearly all forklift attachments will reduce the rated load lifting capacity of the forklift truck owing to two key factors:

- The attachment will add weight to the forklift, lessening its total carrying capacity.

- The forklift attachment will change the weight profile of the forklift truck, typically shifting the centre of gravity forward.

Any reallocation of weight requires a reduction in the maximum load capacity of the forklift to prevent tipovers.

What must you check before using an attachment on a forklift?

As with any piece of machinery, caution must always be exercised when operating a forklift to minimise risk to personnel, goods, and equipment alike.

In addition to the regular forklift operating guidelines, it is of the utmost importance to carry out extra checks when using a forklift attachment. Doing so will not only prevent tipovers, as mentioned previously, but it will also ensure you prolong the life of your machinery and equipment, your goods are handled correctly and with care, and, most importantly, your staff can operate in a safe working environment.

The extra checks that we recommend when using a forklift attachment are:

- Ensure the forklift attachment suits the forklift and truck you are fitting it to.

- Check the attachment suitability for the type of load you are lifting or handling. If in doubt, ask – we have a knowledgeable friendly team of experts who are here to help.

- Last, but not least, inspect the fitting of the forklift attachment to confirm it is properly attached with a suitable locking device.

A safety note on operating a forklift with an attachment installed

In light of the changes to weight distribution, it is advisable to drive and turn slower than normal when operating a forklift with an attachment installed.

Even when the load is empty, the weight profile and driving characteristics of the vehicle are likely to differ considerably from the original non-modified forklift.

Common mechanical forklift attachments:

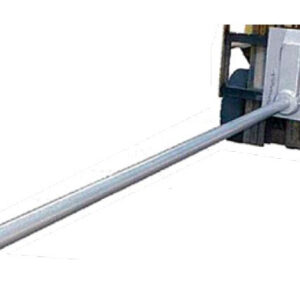

Fork extensions

Designed to extend the length of a forklift’s existing forks. They are available in many sizes, finishes and profiles to meet specific application needs.

Jib crane attachments

These attachments are a slip-on unit that allows the forklift to pick up loads through a lifting eye or by using slings at an extended position.

Man cages

Providing a safe working platform for personnel when lifting them by forklift, man cages are normally rated for a maximum load of 250kg (approximately two workers and their equipment).

Drum handling equipment

Allowing heavy and awkward drums to be moved, lifted or decanted safely and efficiently, forklift drum handling attachments are the safe and efficient option for drum handling.

Self-tipping waste bins

Suitable for all waste handling applications, self-tipping waste bins are used with either a forklift in manufacturing and industry or a crane in construction. These bins make light work of removing and tipping waste product.

Container ramps

Designed for forklift access and bridging into containers from ground level, container ramps are available in a range of different models.

Common hydraulic forklift attachments:

Rotators

An extremely useful attachment which allows you to rotate the forks 360° in a revolving motion, safely and efficiently when moving loads. Best used for inverting and dumping loads, rotators help to improve productivity and greatly limit downtime.

Side shifters

One of the most common attachments used today, side shifters are an attachment that allows you to move a load from side to side, so you can make small adjustments to the alignment of the pallet, without manoeuvring the entire forklift.

Fork positioners

Allow the forklift forks to be positioned hydraulically. Fork positioners are particularly useful when the width of the load changes constantly, allowing the operator to align forks with pallets faster for more effective handling.

Paper roll attachments

Enabling operators to increase productivity while handling large quantities of paper, the paper roll attachment ensures that the paper roll remains undamaged. Commonly used in the paper and printing handling industry, paper roll attachments are made to be suitable for numerous different types of machines.

Push pull attachments

Providing a cost-effective solution, whereby standard wooden or plastic pallets are substituted by an inexpensive slip sheet, the push pull attachment helps to increase shipping volume.

Multiple load handlers

Used to handle both a single pallet, or the forks can be spread hydraulically to lift, carry and side shift multiple pallets side by side, multiple load handlers are a versatile attachment that can navigate through narrow aisles, whilst boosting material handling efficiency by taking fewer trips to get the job done.

Let us do the heavy lifting for you

Forklifts play a crucial role in material handling operations, but are often limited in scope to performing their intended function and that function only. Fortunately, there are now a wide range of optional add-on attachments available for your forklift.

As with all heavy machinery, care must be taken to ensure that any crane attachment meets the appropriate needs of the application and does not exceed technical limitations.

Our knowledgeable team of problem solvers can help you to choose the appropriate crane attachment, increasing the effectiveness of your material handling operation by ensuring you have the “right tool for the job”.

Let us do the heavy lifting for you. Contact us today for an obligation-free consultation and quote.

Showing 1–30 of 79 results

-

250kg Aluminium Man Cage

SKU: FMC-19-123View product -

Sale!

Adjustable Combination Spreader and Lifting Beam

SKU: FSB-09-240View product -

Sale!

Broom Sweeper

SKU: IFMS-Select Options -

Sale!

Bulk Bag Lifter (Slip-On Low Profile) – 1500KG

SKU: FJA-19-211View product -

Sale!

Cable Reel Dispenser (Pair) – 2000KG

SKU: FJA-19-102View product -

Sale!

Drop Bottom Bins

SKU: STDB-Select Options -

Sale!

Drum Dumper

SKU: FDH-18-504View product -

Sale!

Drum Handler (Chain Rotator) – 400KG

SKU: FDH-18-613View product -

Sale!

Drum Handler (Lifting Cradle) – 500KG

SKU: CHA-21-345View product -

Fork Spreader

SKU: FJA-19-628View product -

Sale!

Fork Spreader (No Back) – 2500KG

SKU: FJA-19-6XXSelect Options -

Sale!

Forklift & Crane Drum Rotator

SKU: CHA-21-340View product -

Forklift Rotator – Hydraulic

SKU: SRRB-Select Options -

Sale!

Heavy Duty Tip-Up Bins

SKU: HDTB-Select Options -

Sale!

Hydraulic Drum Rotator

SKU: FDH-18-617View product -

Sale!

Hydraulic Wire Mesh Lifter

SKU: FWMA-5000HView product -

Sale!

Jib (Swing Arm Boom) – 2000KG

SKU: FJA-19-468View product -

Magnetic Rubber Fork Protectors (Pair)

SKU: FP-02-115View product -

Sale!

Man Cage (Order Picker) – 1000KG (Hand Rail Sides)

SKU: CSTM-CGE-1View product -

Sale!

Man Cage (Order Picker) – 1000KG (Mesh Sides)

SKU: CSTM-CGE-2View product -

Man Cage Extension Riser

SKU: FMC-19-140View product -

Man Cage Gate Torsion Spring Assembly

SKU: FMC-12-010View product -

Sale!

Pull Cord Wheelie Bin Tippers

SKU: STWB-Select Options -

Replacement Locking Pin

SKU: LP-12-00Select Options -

Sale!

Rigging Storage Cage

SKU: CHA-21-018View product -

Sale!

Roll Prong (Carriage Mounted)

SKU: RPC-QSelect Options -

Sale!

Rotating and Crane Waste Bins

SKU: STCB-Select Options -

Sale!

Self Tipping Bins (Low Profile)

SKU: STWB-DSelect Options -

Sale!

Small Beak Drum Handler 60 LTR

SKU: FDH-18-508View product -

Sale!

Tapered Spade Drum Handler

SKU: FDH-18-509View product

Product Search…

Products

-

Balken G2 Electric Chain Hoist - Single Speed - 250kg Capacity

Balken G2 Electric Chain Hoist - Single Speed - 250kg Capacity

-

Balken G2 Electric Chain Hoist - Single Speed - 500kg Capacity

Balken G2 Electric Chain Hoist - Single Speed - 500kg Capacity

-

Balken G2 Electric Chain Hoist - Single Speed - 1000 Capacity

Balken G2 Electric Chain Hoist - Single Speed - 1000 Capacity

-

Balken G2 Electric Chain Hoist - Single Speed - 3000 Capacity

Balken G2 Electric Chain Hoist - Single Speed - 3000 Capacity

-

Balken G2 Electric Chain Hoist - Dual Speed - 500 Capacity

Balken G2 Electric Chain Hoist - Dual Speed - 500 Capacity