A wall mounted crane (or wall crane as they are sometimes called) is a type of jib crane, ideally suited for use on busy factory floors and facilities with multiple obstructions overhead. With its jib arm design, a crane mounted to the wall doesn’t require floor space or special foundations to operate and can efficiently fold out of the way of overhead cranes.

On some applications, existing building columns or overhead beams can be used to mount the jib arms on, which means new foundations are not required, saving on costly and time consuming structural building changes.

When to use a wall mounted crane

Wall mounted cranes are great lifting solutions for workstations that are situated close to walls or other vertical elements (columns, beams etc). Wall mounted cranes can also be used underneath other existing crane systems (e.g. overhead/bridge cranes) to provide a dedicated secondary lifting capability, and allow operators to effortlessly and efficiently position loads with precision.

Commonly found in automotive workshops, engineering fabrication facilities, and manufacturing plants, wall mounted cranes operate in a semi-circular area, and are typically designed for interior use. Wall mounted jib cranes can be fitted with either a manual chain hoist or an electric chain Hoist system.

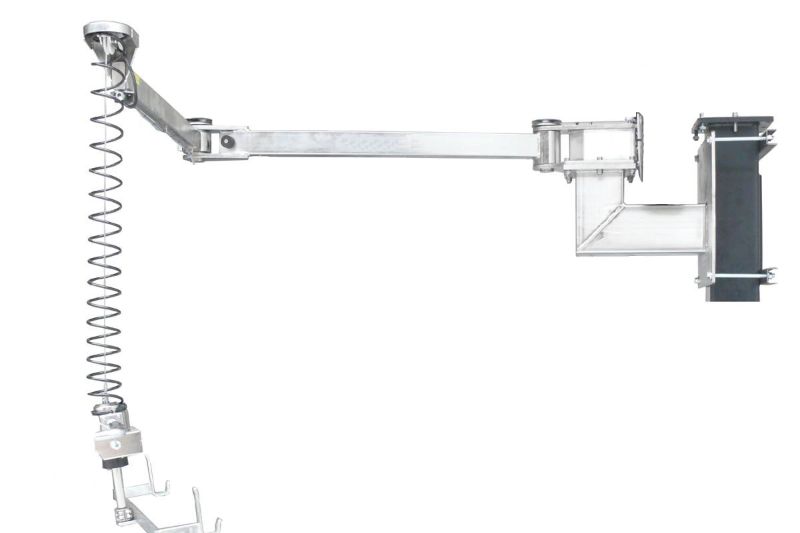

With their independent head assembly, a wall mounted crane comes in two parts, allowing for easier installation. This simple head/boom shaft connection permits separate installation and provides maximum lift for the hoist as it can be installed very close to the underside of the lower ceiling obstruction for improved headroom.

Wall mounted cranes also feature a head retaining pin to provide resistance to accidental upward dislodgement of the head, and precision self-aligning roller bearings in top pivot and trunnion assemblies to ensure smooth operation and longevity.

Stratalign wall mounted cranes

As New Zealand’s industrial crane experts, we supply a range of top quality wall mounted cranes, designed by our engineers to meet exacting application requirements and customised to each workspace.

We use extensive industry knowledge to handpick reputable brands that we know are reliable and safe, ensuring our customers get the right lifting solution product, without having to compromise on quality.

Let us do the heavy lifting for you

Wall mounted cranes can play an important role in many material handling operations; but, as with all heavy machinery, care must be taken to ensure that the appropriate technical limitations of the equipment are respected and its use is as intended.

Our experienced team of engineers and technical staff can help you choose the correct wall mounted cranes setup that meet your needs, improving the efficiency and safety of your material handling operation by ensuring you have the "right tool for the job".

Let us do the heavy lifting for you. Contact us today for an obligation-free consultation and quote.

Applications

Wall Mounted Jib Cranes

Our Process

Hamilton Jet Assembly Plant - Case Study

The Requirement

The Challenge

Solution to a long-standing challenge

As a solution to a long standing challenge, Cabtec Ltd purchased a Fezer vacuum lifter from Stratalign Limited, for processing product through a processing line. Prior to the purchase, the process had required manual handling, which in today's environment, is not a sustainable option.

More than one option for this solution was investigated by Cabtec with the decision being a vacuum lifter as the winning choice. Cabtec's spokesman recalls, Cabtec selected Stratalign as the winning supplier, based on their ability to provide the technical and professional advice, along with what Cabec considered a top quality product for a competitive price

.

The ease of operation

is facilitated by the very smooth running bearings and movement points, integral to this structurally sound piece of kit. He continues, From the day the order was placed, the Stratalign team kept us updated with progress, to the day the machine was installed.

The installation process was organized in such a way, by Stratalign, that it caused absolute minimal disruption to a very busy working environment during normal working hours.