Duty cycles are a critical consideration for any business looking to invest in a hoist.

While hoists may be strong and adaptable pieces of lifting equipment, you can’t just use any old model – the ideal choice will depend on a number of factors: the work environments and limitations of your site, the materials and weights that need to be lifted, how often and how much lifting and shifting the hoist will be required to do.

This last point brings us to the subject of duty cycles, which can be a confusing area even for veterans of the material handling space. So, in this guide, we’ll drill down on this critical measure: what hoist duty cycles are, how they work, and how to use them.

What is a hoist duty cycle?

Hoist duty cycles define how frequently and for how long a hoisting device is able to operate within a given time frame. Understanding hoist duty cycles is the first step to identifying a suitable hoist for your application.

Hoist duty cycles are a key consideration in hoist duty classifications. The more the hoist can be used in a given period and the higher its load capacity, the ‘heavier’ the duty classification. Other classification factors include lifting speed and lifting height.

A side note here: ‘heavy duty’ can be a slightly confusing term in the world of lifting and material handling. In terms of hoist duty cycles, ‘heavy duty’ doesn’t refer to weight, but to how heavily a hoist, including gantry cranes, can be used in a time span.

How are hoist duty cycles calculated?

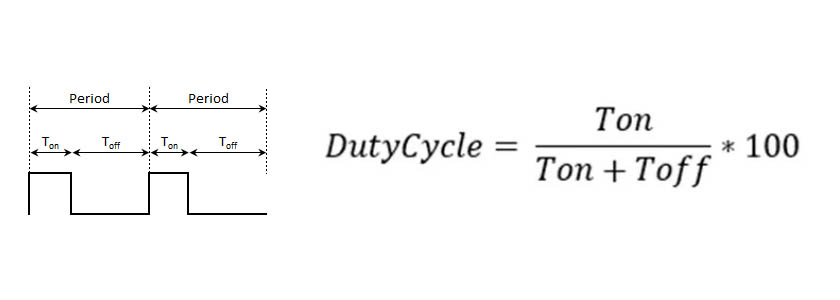

Hoist duty cycles are calculated as the ratio between the operating time and the operating plus standstill time (total time) and usually expressed as a percentage of total operating time. I.e 40% equals 40 minutes operating time for every 100 minutes.

The duty cycle is determined by how much the hoist motor is allowed to heat. The duty cycle of a hoist is usually calculated by getting the motor up to its maximum operating temperature and seeing how long it can continue to perform as it should at that temperature, or how well it can dissipate built-up heat.

How hoist duty cycles effect hoist duty classifications

Hoist duty cycles are a major factor in calculating hoist duty classifications.

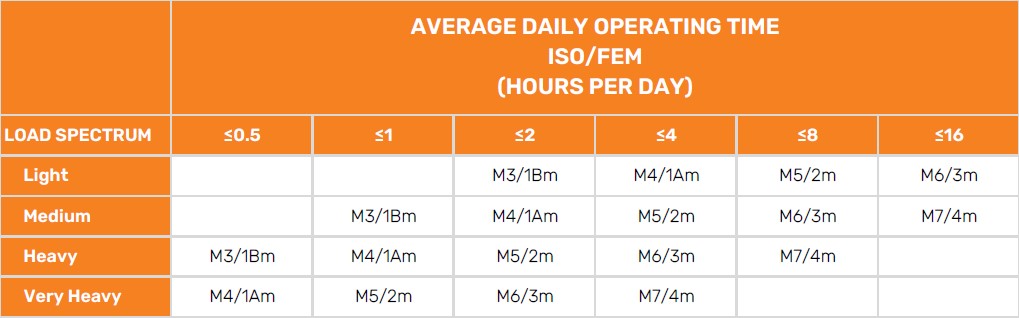

There are two main standards that describe hoist duty classifications: FEM and ISO. Both the FEM and ISO systems split hoists into eight classes:

- FEM: 1Dm, 1Cm, 1Bm, 1Am, 2m, 3m, 4m, 5m.

- ISO: M1, M2, M3, M4, M5, M6, M7, M8.

1Dm/M1 is the lightest duty hoist, 5m/M8 is the heaviest. While using slightly different methods to calculate classifications, both the FEM and ISO systems more or less align with each other.

Hoist duty cycles, including those involving jib cranes, are often converted from percentages and ratios to more easily digestible numbers, such as 'hours per day,' to help material handling professionals understand which duty classification they should be aiming for.

This simplified duty cycle measurement and an idea of load capacity can be enough to identify the hoist classification you should choose in a given situation.

Helping New Zealand manufacturers safely solve their lifting challenges with the best local and global solutions

Choosing the right hoist for your situation can be a more complicated process than you might realise. Between chain hoists, air hoists and electric hoists, between load capacities and duty cycles, there can be a lot to wrap your head around.

At Stratalign, we’ve built a reputation for helping Kiwi businesses identify and secure the hoists, portable lifting cranes, and other lifting equipment they need to work better. Our team has the knowledge and expertise you need to identify the ideal lifting equipment for your situation – the type that can make your business safer, more efficient and more productive than ever before.

We offer a complete range of hoists, including electrical, air and manually powered hoists, chain and wire rope hoists, and all the parts and accessories your business may need to adapt a solution to your situation. All our hoist products are also certified to the relevant Australian Standard, AS 1418.1.