Battery-powered vacuum lifters are a type of specialist lifting device that use suction cups to grip and lift objects, proving a popular choice due to their ability to significantly speed up material handling applications, while keeping operator safety paramount.

Available in a variety of sizes and capacities to suit different lifting applications, battery-powered vacuum lifters can be used to lift and transport a wide range of materials, including glass, metal, wood, plastics, concrete and more.

Often used in situations where manual lifting would be difficult or dangerous (such as when lifting heavy or awkwardly shaped objects), battery-powered vacuum lifters are commonly found across a wide range of workplaces such as manufacturing plants, construction sites, and warehousing operations.

Why use a battery-powered vacuum lifter?

The major advantage of battery-powered vacuum lifters is that unlike traditional lifting equipment, which require a set power source and therefore can be somewhat cumbersome to mobilise, battery-powered vacuum lifters are highly portable and are able to be used without any external power source - no installation or connection required.

In addition to this mobility, which allows them to be easily moved around the worksite or factory floor, electric vacuum lifters are also relatively easy to operate, requiring only minimal training for safe and effective use. As such, battery-powered vacuum lifters are considered to be a safer alternative to many types of traditional lifting equipment, as their design minimises the risk of injury by reducing the likelihood of back strain or other lifting-related injuries.

Materials are also less likely to be damaged during the lifting process, as the suction cups provide a gentle and secure grip on the object.

And yet another advantage of battery-powered vacuum lifters is their versatility, as they can be used with a variety of lifting accessories, including extension arms and different suction cup configurations, to accommodate different types of materials and lifting situations. This flexibility makes them a popular choice for a wide range of lifting applications, and ensures that they “earn their keep” as a flexible, hard-working asset.

How do battery-powered vacuum lifters work?

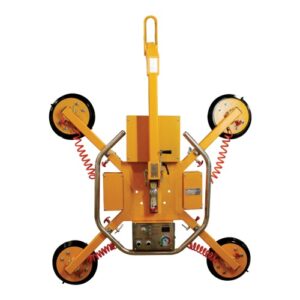

Battery-powered vacuum lifters consist of a vacuum pump, a suction pad or cup, and an electrical battery source that powers the device. When the suction pad is placed on an object, the vacuum pump creates the necessary suction to hold the object securely in place, with the operator able to control the lifting and lowering of the object.

In keeping with their safety-first approach, battery-powered vacuum lifters are often equipped with safety features, such as audible and visual alarms to indicate low battery levels or suction failure.

One popular application for battery-powered vacuum lifters is in the installation of glass panels in building construction. Glass panels are cumbersome at the best of times - heavy and fragile - difficult to handle and transport safely. Battery-powered vacuum lifters solve this problem by providing a secure grip on the glass, allowing it to be lifted and transported with ease, while ensuring a tight seal at all times. This helps to mitigate risk not just to personnel, but to the financial balance sheet too, as large glass panels can be costly to replace.

Stratalign battery-powered vacuum lifters

As New Zealand’s material handling equipment experts, we supply a range of high quality, mobile, lightweight battery-powered vacuum lifters, with ergonomic handles for easy manoeuvrability and ease of use.

We’ve used our extensive industry knowledge to handpick reputable brands that we know are reliable and safe, ensuring our customers get the right lifting solution product, without having to compromise on quality.

Let us do the heavy lifting for you

Battery-powered vacuum lifters can play an important role in many material handling operations, but, as with all heavy machinery, care must be taken to ensure that the proposed usage meets the appropriate application and does not exceed technical limitations.

Our knowledgeable team of problem solvers can help you to choose the correct battery-powered vacuum lifter setup for your situation, improving the efficiency and safety of your material handling operation by ensuring you have the “right tool for the job”.

Let us do the heavy lifting for you. Contact us today for a consultation and quote.

Applications

Our Process

Tawa Door Company - Case Study

The Requirement

The Challenge

Solution to a long-standing challenge

As a solution to a long standing challenge, Cabtec Ltd purchased a Fezer vacuum lifter from Stratalign Limited, for processing product through a processing line. Prior to the purchase, the process had required manual handling, which in today's environment, is not a sustainable option.

More than one option for this solution was investigated by Cabtec with the decision being a vacuum lifter as the winning choice. Cabtec's spokesman recalls, Cabtec selected Stratalign as the winning supplier, based on their ability to provide the technical and professional advice, along with what Cabec considered a top quality product for a competitive price

.

The ease of operation

is facilitated by the very smooth running bearings and movement points, integral to this structurally sound piece of kit. He continues, From the day the order was placed, the Stratalign team kept us updated with progress, to the day the machine was installed.

The installation process was organized in such a way, by Stratalign, that it caused absolute minimal disruption to a very busy working environment during normal working hours.