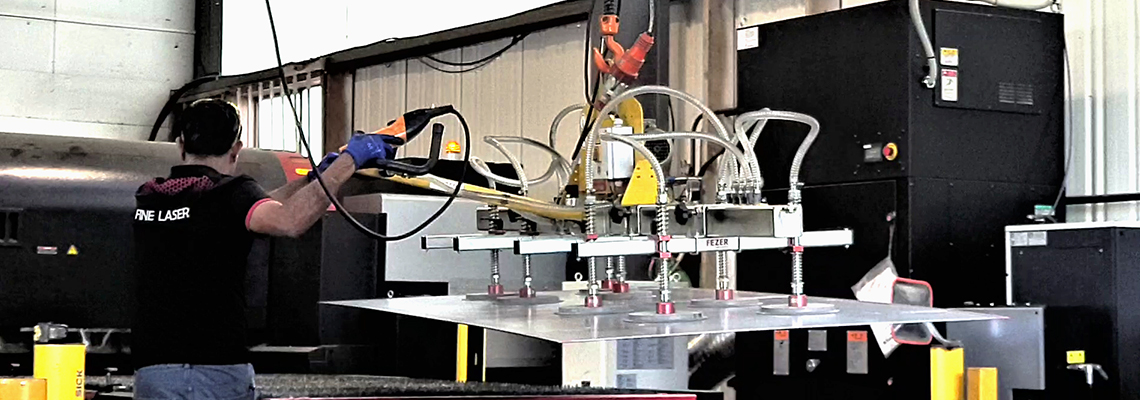

Fine Laser Cutting – Vacuum Lifting and Sheetmetal Handling

The Requirement:

Fine Laser Cutting, a Papakura based sheet metal services company, had a manual handling challenge with their lifting and handling of sheet steel onto the bed of their laser cutting machine.

Different thickness sheet metal, both ferrous and non-ferrous needed to be safely handled and business growth meant that efficiency gains were looked for to increase the throughput and minimize downtime of the laser machine.

The Challenge:

Although a vacuum lifting system was the obvious choice for this application, the challenge lay with building a support structure to hang a lifter off. Also, as a growing business, Fine laser needed the assurance that their machinery could come with them should they outgrow their current premises.

The Solution:

- Our Design and Sales Team worked together to provide our client with a complete turnkey solution to this challenge.

- Working with Fezer Vacuum Lifting from Germany for the VacuBoy Lifter and Erikkila from Finland for the monorail, provided a brilliant hand in glove combination to overcome every obstacle that presented itself.

- The dual track monorail simply attached to the existing structure meaning that the investment is smart and flexible and will grow with the business, all the while supporting sheets of steel of up to 900kg.

- Our trained and competent lifting equipment engineers applied their knowledge and experience to complete the design, manufacturing, and supply within the allotted time.

- What used to be a 2-3 man operation, taking 10 minutes, is now done safely in a 30 second operation by one man says Managing Director Uthaman Thiru.